A Blog

digital musings.

Tissue Culture Experiments

tags: micropropagation - tissue culturePlant propagation has always been fascinating. From the Nuclear Gardens and Rio Red Grapefruit of the 1970s to the glowing petunias of today, there has always been something interesting about growing plants.

Another fascination of mine is artificial reward systems - like in game economies. From “Destroying the Economy on Minecraft’s WORST Pay-to-Win Server” to “How the Runescape Economy Works! (and how to take advantage!)” fake incentive markets are my version of murder mystery podcasts. So when a video entitled “I accidentally crashed the rare plant market “ came across my feed it piqued my interests. Enough so to invest in a kit and try it myself.

The Setup

- Digital Scale

- pH Meter and Solution

- Microwave Safe Glass Measuring Cups

- 50ml Plastic Centrifuge Tubes with Screw Cap (10x)

- Bleach (6%)

- Distilled Water

- Plants in Jar Starter Kit

The Recipe (100ml)

Sterilizing the media is very important, but busting out a pressure cooker might be too much. We will use a mixture of microwave and chemical sterilization for this run. If it fails then we will look into a more proper setup.

This first batch will be a small test brew for testing purposes. Each tube will get 10ml of media solution.

Ingredients

- 100ml Distilled Water

- 0.45g MS Medium

- 3.00g Sucrose (Sugar)

- 0.05ml BAP (1mg/ml)

- 0.01ml NAA (1mg/ml)

- 0.70g Agar

- 0.5ml Bleach (see table below for dilution instructions)

Process

-

Combine Agar, MS powder, and hormone stocks (BAP and NAA) in approximately 75ml of distilled water.

-

Stir until all dry ingredients are suspended.

-

Add distilled water until the total volume reaches exactly 100 ml.

-

Adjust the pH to 6. This step is critical; if the pH is incorrect, the bleach will not effectively sterilize the media or may become toxic to the plants.

-

Heat the solution (microwave or stovetop) just until it boils and the liquid becomes transparent.

-

Remove solution from the heat source.

-

Stir in sucrose until fully dissolved.

-

Add 0.5ml of a 1:10 diluted bleach solution (created by mixing 1ml fresh bleach with 9ml water). Mix vigorously for 30 seconds.

-

Quickly dispense 10 ml of the liquid media into each tube.

-

Leave the caps loose for 10 minutes. This “off-gassing” period allows excess gasses to escape, preventing chemical damage to your explant.

-

Tighten the caps once the media has gelled.

First Run

Next we monitor the tubes for 24 hours. Tubes should be clear. If there is any sign of discoloration or fuzziness that indicates a failed sanitization process and we will need to adjust our sterilization technique.

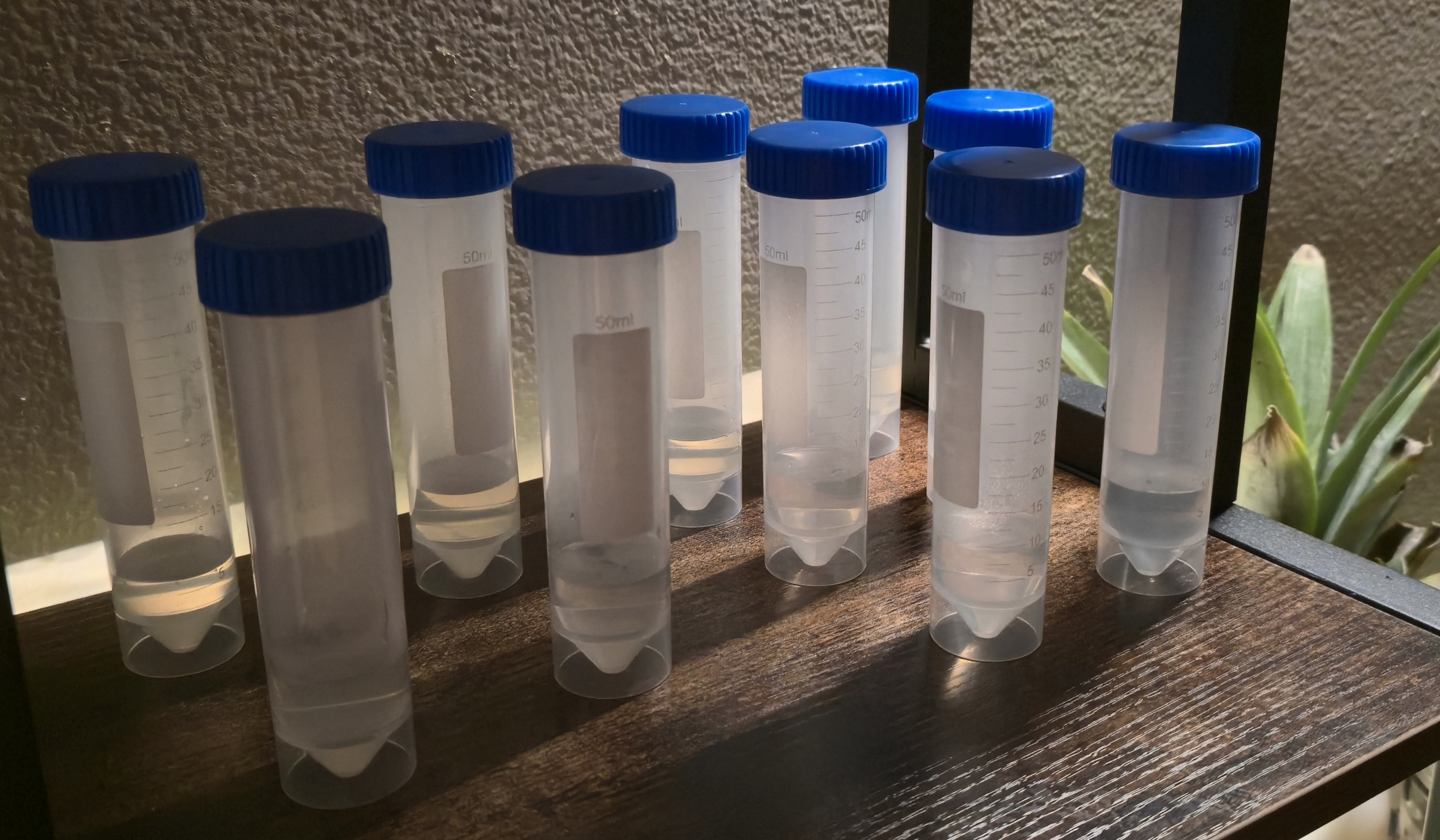

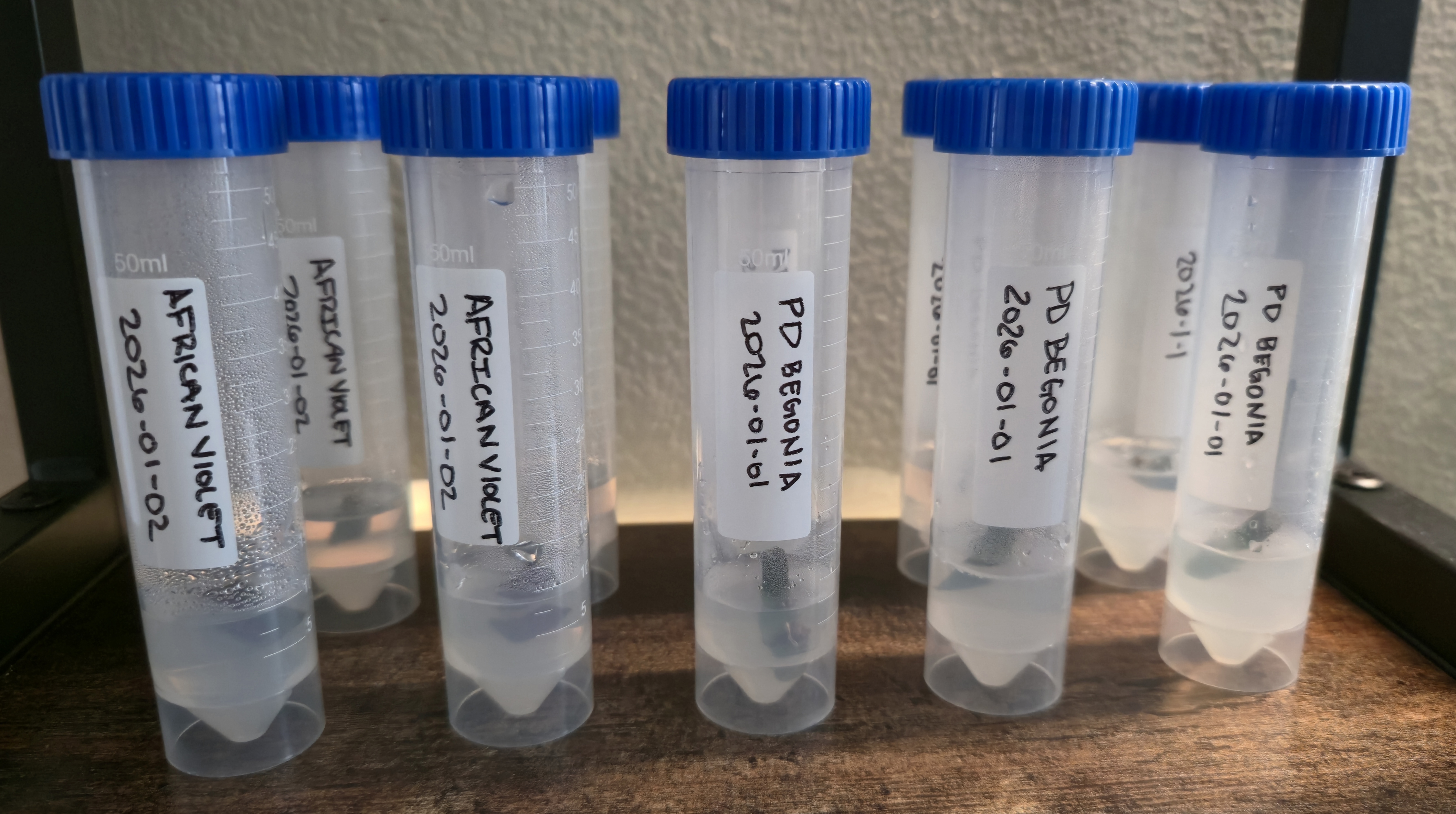

Initial Pour (0 Hours)

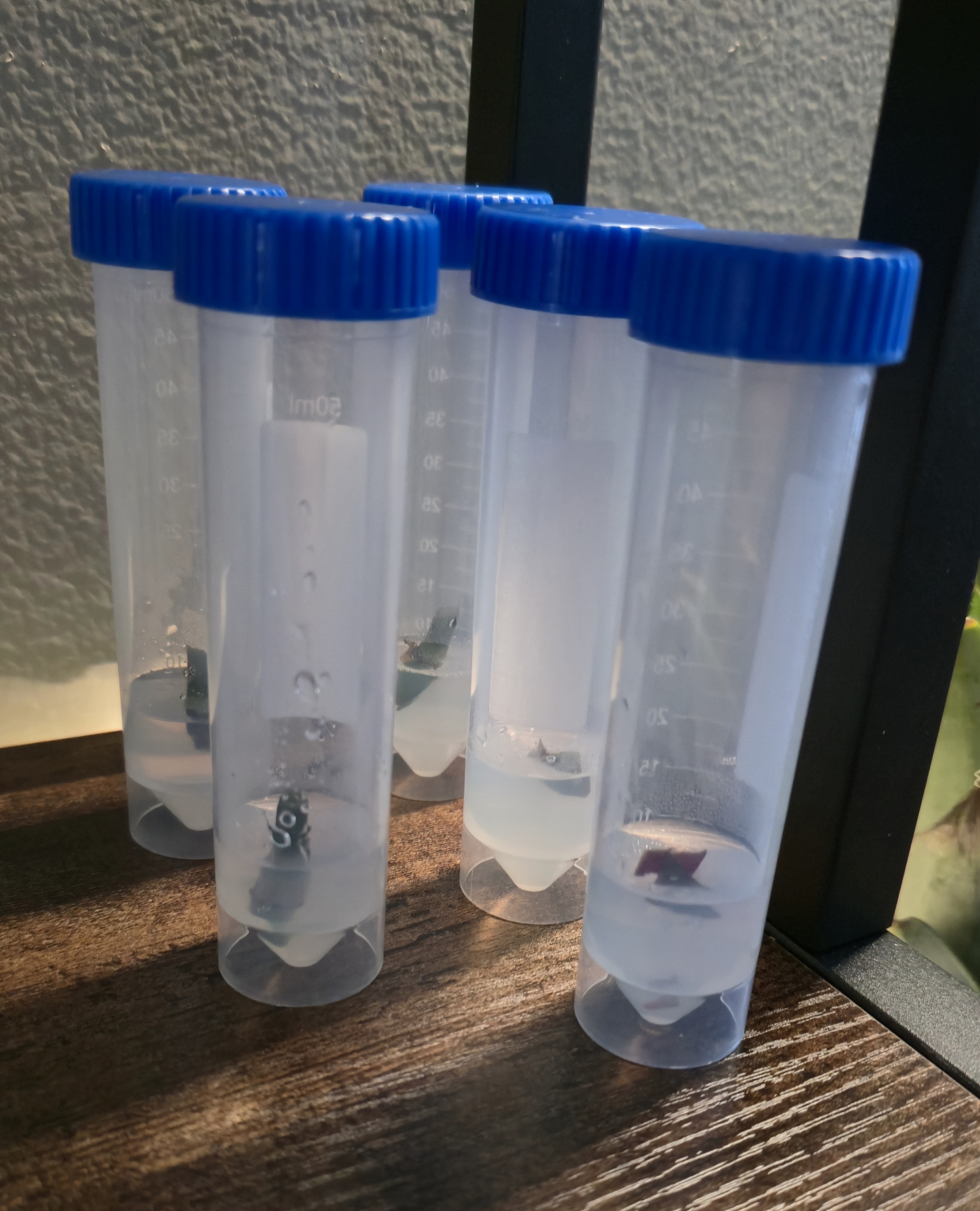

24 Hours Later

Results

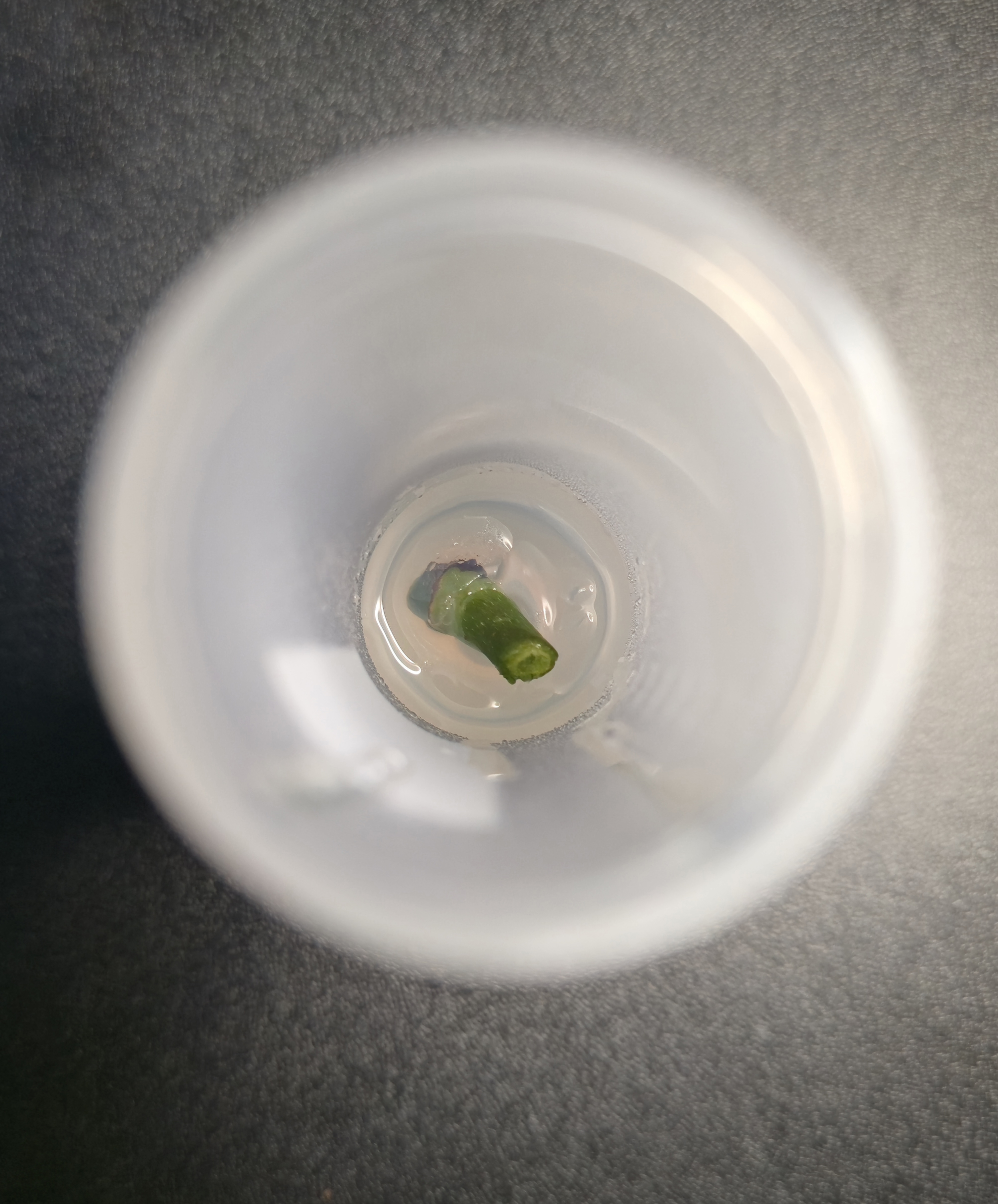

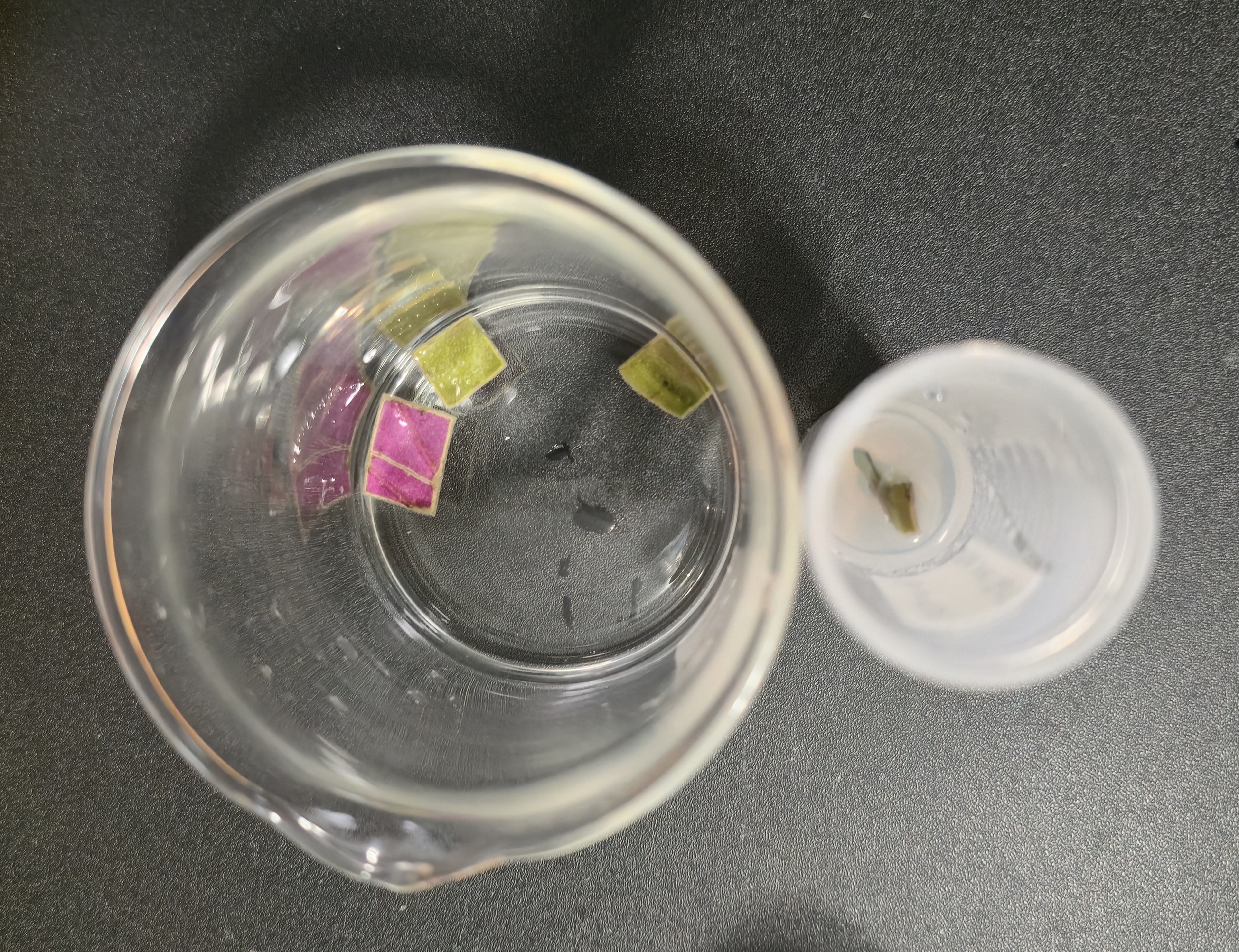

Explant Sources: African Violet (Saintpaulia) leaf sections and Polka Dot Begonia (Begonia maculata) leaves and nodes.

Surface Sterilization Protocol:

- 10-minute soak in 10% bleach dilution (0.6% active chlorine)

- Triple rinse with sterile distilled water

- Dissection performed in makeshift sterile field

Both the leaves and nodes of the begonia will be used for establishment. For the African Violet we will use only leaf sections. The African Violet sample was taken from a healthy parent plant but the leaves are older and may not respond as well.

The first tubes were planted after 24 hours of observation with begonia explants.

Author’s Note: It was at this point they realized that they had only added 0.05ml of bleach solution instead of 0.5ml. Because of this 5 were planted and 5 were left as controls to see the difference in contamination rates.

48 Hours Later

After 48 hours there were no visible signs of contamination in the control tubes so they were planted with the african violet explants.

Now we wait.

Week 1

One of the begonia tubes showed signs of contamination after a week. The rest appear clean. We will be saving the contaminated tube for experiments with peracetic acid - we are ruining too many tshirts.

Notes and Tables

Media Scaling Table (0.003% Chlorine Target)

| Ingredient | 100ml Batch | 500ml Batch | 1L Batch |

|---|---|---|---|

| Distilled Water | 100ml | 500ml | 1,000ml |

| MS Medium Powder | 0.45g | 2.22g | 4.43g |

| Sucrose (Sugar) | 3.00g | 15.00g | 30.00g |

| BAP (1mg/ml) | 0.05ml | 0.25ml | 0.50ml |

| NAA (1mg/ml) | 0.01ml | 0.05ml | 0.10ml |

| Agar | 0.70g | 3.50g | 7.00g |

| 1:10 Bleach Dilution | 0.50ml | 2.00ml | 4.00ml |

1:10 Bleach Stock Solution Scaling Table (0.6% Final Concentration)

This table is for creating the 1:10 Bleach Dilution used in the media sterilization process. This stock solution is used to precisely measure the small amounts of chlorine required to reach the ~0.003% active chlorine target for the culture media.

| Desired Stock Volume | Household Bleach (6%) | Distilled Water |

|---|---|---|

| 10 mL | 1 mL | 9 mL |

| 50 mL | 5 mL | 45 mL |

| 100 mL | 10 mL | 90 mL |

Procedural Reminders

- Safety First: Be smart. Do this in a well-ventilated area and wear gloves and eye protection when handling bleach.

- pH Adjustment: Aim for a pH of 6.0 ± 1 for this method

- Bleach Timing: Add the bleach dilution after the agar has been heated and dissolved, but while the liquid is still hot to ensure distribution.

- “Gas-Off”: Leave caps loose for 10 minutes in a sterile workspace to allow excess chlorine to volatilize.

- Verification Period: Allow the media to sit for 24-48 hours before inoculation to ensure no visible microorganism growth appears.

Lessons Learned

-

For this run I did not have a pH meter so I was not able to adjust the pH. This is critical for future runs.

-

It would be beneficial if the sucrose could be added after microwaving to prevent breakdowns.

-

A more controlled setting would be beneficial for testing different recipes and techniques.